We get asked sometimes…

Loads of room for a 2.25 with the sliders right up to the front, wouldn’t go any bigger or mud clearance might become an issue.

You won’t get tyre rub on the frame, even when really stomping. I can get the front mech to touch the (2.25″) tyre, just, in granny ring (and obviously riding SS you won’t have a front mech to care about!), but it won’t get near the frame unless you’ve got really REALLY flexy wheels!

Couple of pics attached to give an idea of clearance/how far forward the sliders are (sorry about the silly large size)

shedfire

See the thronging masses at the Ragley Seminar…

shedfire

Ragley Seminar at Bristol Hotlines show

Hotlines are our distributors in the UK, and they have eschewed the typical bike show in favour of regional “roadshows” where we turn up in key cities around the UK and put our own show on, rather than pay the really ludicrous amounts that national show organisers charge. Truly, we can do four shows in four cities for less than the cost of one show in London. It’s nuts.

Last night we were in Bristol, and had our first “Ragley Seminar”, a nice event – 20-30 people sat around on chairs (we nearly ran out, and people were standing up) listening to me talk about how I ended up here (in life terms, not the M62, M6, M5…) and some Q&A’s about everything from hydroformed tubing molds, to patterns (oh, no, patents, sorry), to “the biggest rip-off in the bike industry”. It was good fun, seemed to go down well, and we’ve got another planned for the 17th November in Manchester. More details on that show when we’ve a location – if anyone has any details of any nice exhibition space (3-3500sq ft) in Manchester area, let us know.shedfire

Peter Mac’s TD-1

shedfire

Best Ragley review ever – yeah, we think he gets it…

“The Ti Ragley though – feck me what a bike! Insolent like a teenager in puberty and as randy as one on heat. It’s a ‘take me by the scruff of the neck, get right over my front, push my face into the dirt you mother fu**er and absolutely wring seven bells of sh*t out of my scrawny, tight, stiff titanium arse’ kind of bike. It’s a 19 year old with all the soft bits still taught as a drum but smooth when you climb onboard; a slip sliding, sh*t spitting, sideways sha**ing ragger of a bike and it’s fecking brilliant.”

from http://www.singletrackworld.com/forum/topic/to-buy-ti-or-steel#post-1900953

shedfire

Ragley CNC Ti Belt Buckle, from Lynskey – Mark made me a belt :-)

shedfire

Ti Ragley Piglet first sample – in transit now.

shedfire

Bagger 288 – Pre-stickers, pre-show…

shedfire

Ragley 2011 Catalogue

shedfire

Ragley 2011 :: Fat Head Tubing

We love steel tubing – and so do you guys – our steel frame outsold our alloy one by a factor of 10:1 (well, until someone dropped the price right down to clear the alloy ones out!). But steel tubing was a bit of a dull thing. We thought we’d spend time thinking and working on it to make it better.

How do you improve on a product that’s been around for ages? Show it off!

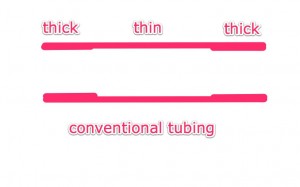

Conventional tubing is very clever. It starts off as a round tube with all the tube the same thickness throughout. Then, using metal trickery, the tube is thinned in the centre – BUT THE OUTSIDE DIAMETER STAYS THE SAME. It’s a drawing and re-drawing process, and it’s very neat and smart, but basically it hides all the clever stuff away inside.

Everyone uses tubing like this. It’s really hard to make, but that uniform outside diameter, with hidden thinned walls is the way its done. We thought that was silly.

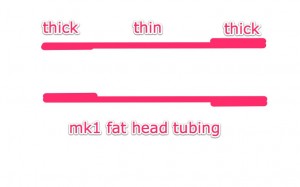

For our first Blue Pig frames, we used a tube on the top tube of the bike that had a thicker section at the head tube end. This tube was originally designed as a seat tube, but we liked the thicker head tube section which let us do clever things with transfer gussets and stuff to beef the front of the frame up without adding too much stiffness. Remember – a larger diameter tube is stronger than a smaller diameter one of the same weight. But it’s a lot stiffer too. And whilst stiffness is great in some areas of a bike, too much stiffness in some areas is bad.

Our Mk1 Fat head tubing therefore, was just with an external butt at the end. The tube just got thicker, but stayed the same diameter inside. It was half way there. We liked the external bulge, and it did a lot in terms of strength, but we knew we could do it better.

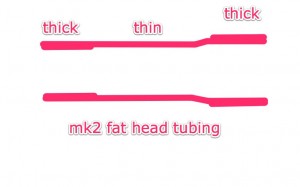

And lo… Mk2 Fat Head Tubing. The stressed end of the tube gets fatter, as well as the wall getting thicker. Taming those stresses with increased diameter and increased wall thickness, all in a dynamic way you can see. We use this on all our steel frames for this year. It means we can remove external saddle gusseting though of course, we still keep our box-head gusset on the back of the head tube which braces the back of the head tube and strengthens the junction of the main tubes and the head tube.

And lo… Mk2 Fat Head Tubing. The stressed end of the tube gets fatter, as well as the wall getting thicker. Taming those stresses with increased diameter and increased wall thickness, all in a dynamic way you can see. We use this on all our steel frames for this year. It means we can remove external saddle gusseting though of course, we still keep our box-head gusset on the back of the head tube which braces the back of the head tube and strengthens the junction of the main tubes and the head tube.